What is Braided Copper? Understanding Its Uses and Benefits

2025-06-06

Copper is widely recognized for its excellent conductivity and durability, making it an essential material in electrical systems, plumbing, and a range of industrial applications. One form of copper that has gained significant attention is braided copper. Whether it's for electrical wiring, grounding systems, or flexible connections, braided copper has unique properties that set it apart from solid copper wires. In this blog, we’ll dive deep into what braided copper is, its uses, and why it’s such a vital material in modern technology.

What is Braided Copper?

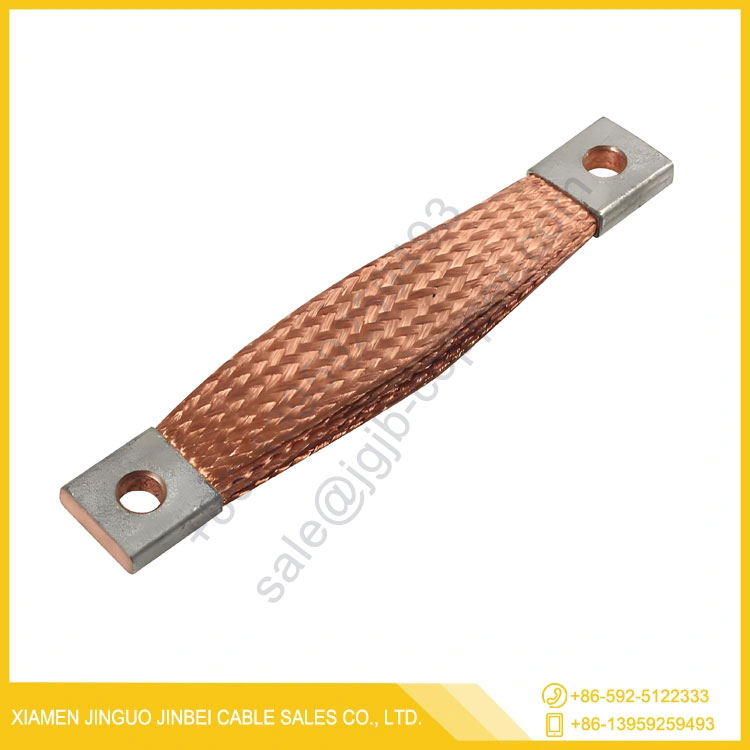

Braided copper is a type of wire formed by weaving multiple strands of copper wire together, creating a flexible, durable, and conductive material. The braiding process involves interlacing the individual copper strands in a crisscross pattern, which enhances the material’s strength, flexibility, and conductivity. Braided copper is typically coated with a layer of tin or other metals to further improve its corrosion resistance.

The braid structure allows the copper to bend and flex easily without breaking, making it an ideal choice for many applications where flexibility and strength are required. The most common type of braided copper wire is tinned copper braid, which is used for both electrical and mechanical purposes.

Common Applications of Braided Copper

1. Electrical Grounding Systems:

Braided copper is widely used in grounding systems because of its excellent electrical conductivity and flexibility. In electrical installations, it is essential to ensure that there’s a path to safely discharge excess electricity into the ground. Braided copper grounding cables are used in power plants, substation equipment, and industrial machinery to maintain safe electrical systems.

2. Flexible Electrical Connections:

The flexibility of braided copper makes it an excellent choice for creating flexible electrical connections. Braided copper wire is often used in transformers, motors, circuit boards, and cable connectors. Its flexible design ensures that electrical systems remain intact even when subjected to vibrations or movement, which could cause rigid connections to break or degrade.

3. Electromagnetic Shielding:

Another notable application of braided copper is in electromagnetic interference (EMI) shielding. Braided copper is used to wrap around cables and wires, preventing external electromagnetic waves from affecting the signals inside. This is particularly important in industries like telecommunications, broadcasting, and aerospace, where signal integrity is paramount.

4. Plumbing and HVAC Systems:

Braided copper is also commonly used in plumbing and heating, ventilation, and air conditioning (HVAC) systems. Braided copper hoses and connectors are often used in high-pressure environments, such as gas or water lines, because they offer flexibility and resistance to wear and tear. These hoses are often used in places where there is a need for continuous movement or slight changes in position.

5. Battery and Power Supply Systems:

Braided copper is frequently used in battery terminals, solar power systems, and other power distribution applications. The ability of braided copper to handle high currents while maintaining flexibility and strength makes it a reliable choice in these settings.

Why Choose Braided Copper?

1. Flexibility and Durability:

One of the primary benefits of braided copper is its flexibility. The interwoven design allows it to bend and flex without breaking, which is essential for applications where rigid wires would be prone to failure due to constant movement or vibration. This flexibility also makes it easier to install in tight spaces or around corners.

2. Excellent Conductivity:

Copper is one of the best conductors of electricity, and braided copper maintains this characteristic. The increased surface area of the strands in the braid helps to improve conductivity even further, making it an excellent choice for high-performance electrical systems.

3. Corrosion Resistance:

Tinned copper, often used for braiding, has superior resistance to corrosion, making it suitable for use in harsh environments or outdoor applications where moisture, salt, and other corrosive elements are present.

4. Heat Resistance:

Copper’s natural heat resistance makes it ideal for systems that operate under high temperatures. Whether in electrical circuits or plumbing systems, braided copper can handle heat without losing its structural integrity.

5. Cost-Effective Solution:

While pure copper can be expensive, braided copper offers a cost-effective solution for various applications. By using multiple strands, manufacturers can provide a flexible, durable, and conductive solution at a competitive price point.

Braided copper is an incredibly versatile and valuable material used across a wide range of industries. From electrical grounding systems to plumbing and HVAC applications, braided copper combines the best of copper’s conductivity, flexibility, and corrosion resistance. Its widespread use in both industrial and residential applications speaks to its effectiveness and reliability. Whether you are dealing with complex electrical installations or simple plumbing, braided copper is a dependable choice for the job.