What is petroleum resin used for?

2023-11-20

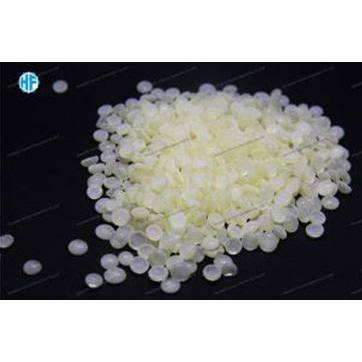

Petroleum resin, a type of resin derived from petroleum or hydrocarbon-based sources, finds application in various industries due to its versatile properties. Here are some common uses:

1. Adhesives: Petroleum resins are used in adhesive formulations for products like tapes, labels, and various types of glue. They help improve tackiness, adhesion, and cohesion in adhesive formulations.

2. Printing inks: In the ink industry, petroleum resins are used as binding agents in the formulation of printing inks. They enhance the ink's adhesion to the substrate, improve color properties, and provide gloss and durability to the printed material.

3. Paints and coatings: These resins are added to paint and coating formulations to improve properties like hardness, gloss, and adhesion. They act as binders and modifiers in the formulation of solvent-based or water-based paints and coatings.

4. Rubber compounding: Petroleum resins are used in the rubber industry as tackifiers and reinforcing agents in rubber compounding processes. They improve the processing characteristics of rubber compounds and enhance properties such as tack, adhesion, and heat resistance in the final rubber products.

5. Tires and rubber goods: In the tire industry, petroleum resins are utilized to improve the performance of tires by enhancing their grip, wear resistance, and overall durability.

6. Industrial applications: They are employed in various industrial applications, such as in the manufacturing of varnishes, sealants, caulks, and as components in electrical insulating materials.

Petroleum resins offer a range of characteristics depending on their specific chemical composition and molecular weight. Manufacturers often tailor these resins to meet the particular requirements of different industries and applications, making them valuable in a wide array of products and processes.